更新時間:2021-04-08

Clothing cutting model put the seam, markings and text labels

First, cut the model put the seam

Sewing also known as sewing, sewing, sewing head, etc., refers to the various pieces of clothing required for each suture plus width, in cm as a unit. Sewing is mainly based on the garment design requirements, the fabric structure and sewing process requirements and other factors to decide. The importance of putting the correct seams has been elaborated in Chapter I, where only the specific requirements and methods for drafting seams are described.

1. Garment design requirements Here refers to the requirements of clothing styles, such as the Department of Ming line parts, must be based on the design line width requirements, then put the seam, the following hem, cuffs hem, Using a series of bright line design situation. The wider the open line, the more seams. In addition also with the grade of clothing design, technology and so on. High-end tri-fold edge process, the lower end of the seam process can be used. For example, the general high-end tri-fold put the stitching: thick material for the line + 0.6 ~ lcm; thin material trifle put the sew to the line width × 2; low seam sewing process put the line for the line width +0.5 cm. For the design of higher apparel. Then the mouth part of the request is thin, put the sew to be less, but increased the difficulty of the sewing process. For foreign trade single processing of clothing, customers to put the sample is how much, then cut the model must put the number of seams, are generally not allowed to change.

2.Fabric structural performance Putting the seams must take into account the structural characteristics of the fabric, the structure is more loose and easily scattered fabrics (such as polyester, etc.), the seam to be properly widened.

3. Sewing process requirements Various types of sewing as shown in Table 2-1.

(1). Flat seam

The two layers of sewing material relative to the front line of the seam type, seam 0.8 ~ 1.2cm, commonly used 1cm. Such as the stitch back side of the known as the inverted seam; stitched separately hot ironing is called a slit; collar, flap and other stitches after the turn is good, called the seam, the seam seam is generally 0.6cm . Flat seams are widely used in the upper garment shoulder seam, side seam, sleeve seams, pants under the file seam, side seam, collar, flap and other parts, flat seam is the most widely used in all kinds of seam type.

(2). Compression seam

Sewing seam, also known as buckle seam. The first seam sewed top deduction, flattening, pressing a positive line 0.1cm line, commonly used in patch bags, shirts and so on, shoulders are generally 0.6 ~ lcm.

(3). Inside seam

The package seam also known as anti-seam. The sewing material will be the front of the relative overlap, a wide and narrow head of the seam, when the first joint wide-brimmed out of the seam over the fold, wrapped in the film on the stitching, stitching in the turn stitching stitch on the line, and then In the net edge of folding 0.1 cm wide open bright line. The characteristics of the amount of positive visible a line, the opposite two lines. Commonly used in shoulder seam, side seam, sleeve seam and other parts, seam wide side is 1.4 ~ 1.6cm, narrow side is 0.7 a 0.8cm.

(4). Outsourcing seam

Outsourcing is also known as the package seam. The opposite side of the sewing material overlap, and then by the method of lining seam line, the formation of Ming Bao Ming's series of sewing. Its characteristic is the front has two lines, the opposite side line. Sewn copies with the package seam.

(5). To seam

The opposite of the first two pieces of clothing, in the front of the narrow slit about 0.3 ~ 0.4cm wide, and then turned over to the opposite side of the fold folded into the light stitches stubble, line of about 0.5 to 0.6 cm wide So come and go seam sew or 1cm. Apply to the material should not be three-seam package, such as thin fabrics such as silk, or no over-sewing machine when used.

(6). Lap seam

Lap seam also known as riding. The two pieces of stitching seam stitching overlap, in the middle of a series of lines to be fixed, can reduce the thickness of the stitching, for a variety of lining cloth stitching, stitches generally 0.8 ~ lcm.

(7). Sit seam

Sit seam refers to the inverted seam on the side of the seaming head series. As the design requirements of the open line width ranging, so plus put the seam is also different. The upper seam of inverted seam is narrower than the width of bright thread in order to reduce the thickness of the seam, while the lower seam of the inverted seam should be wider than the width of 0.4cm so as to fix the open thread and fix the reverse seam. If the front piece of sewing head to keep the first 0.6cm, then the film must be left l cm of the sewing head; thick material coat swing seam shoulder shoulder line width of 2 cm, the back piece of the seam 0.6cm, 2.4cm. For thin clothing, inverted seam of the line is narrower, two pieces of side seam left the same width of 1cm.

(8) Trifold edge

Tucker refers to the material to a seam of about 0.6cm folded, and then folded a width of the seam, such as 1cm, 2cm, etc. (according to design requirements), and then edit a bright line. Trifold for the hem and so on. For silk fabrics, especially the more transparent silk fabrics, tuck the two-fold seam shall be the same. For the bottom pendulum, cuffs, kerchief fold the general put the seam 3 ~ 4cm. Zipper, sacks on both sides of the put the seam is generally 1.5 ~ 2cm.

4. Cut the model put the seam method

(1). Release the seam principle Putting the seam must be based on the size of the seam, the hair suture line with the model of the net suture line parallel, that is parallel plus principle (Figure 2-).

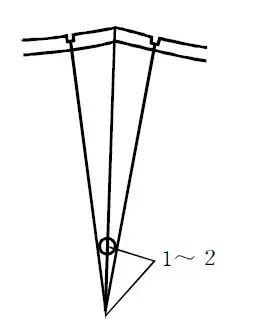

(2) .Slotting method To suit the sleeve as an example, according to the principle of parallel plus and place can be easily and quickly to put the seam. However, when the sewing sleeve sewing thread, due to the length of the end of the seam length, sewing is prone to misalignment, the sewing accuracy drops. To solve this problem, we must take the following methods: First, hit the knife on the suture eye knife; Second, the angle of the sewing head made of quadrilateral, and the corresponding equal. The only way to ensure sewing quality (Figure 2-9).

Specific method:

(1) is to use the need to extend the need to suture the net suture, and intersect with another suture, cross the intersection of suture extension line of the vertical line, you can sew a quadrant;

(2) is stitched and then divided into the shape shown. Quadrilateral plus end angle seam head, there are exceptions, such as jackets, jackets and other non-profit, the neckline and armhole at the corner if you still add the above method, the seam will be found after the missing part of the seam , After the assembly with other components is neither solid nor esthetic, in order to solve this problem, we must take two seam head width to do the end seam, the size of both ends of the seam, so you have to hit the suture Right knife eye. Suture and then split, and the excess part of the clear cut (Figure 2-10).

(3). The end of the pendulum, Kukou, cuffs and other parts of the flanging put the use of hemming Shendao law, the fold will be folded along the fold line up, and then cut directly according to the wool suture, You can (as shown in Figure 2-11). Another method is drawing method, applicable to unfold the cardboard, that is the center line of the fold line, folded according to the width of the fold after the put suture, put the suture by the symmetry principle (Figure 2-12 Shown).

Second, the model tag

Net model according to the above principles and methods put the seam after the hair become a model, the model must be made on a variety of markers, mainly used as model push files, nesting, sampling and cutting the positioning basis to ensure Product specifications and modeling accuracy. Therefore, the model mark is very important, requires careful, serious, not missing. Markers mainly include playing knife eye, drilling, provincial and pleated collapse and so on. l. Knife eye knife also known as the eye knife, notch and so on.

(1). The role of playing knife eye knife can show the size of the seam, play the role of knife and positioning.

(2). Kind of eye type

① scissors play knife eye advantage is convenient, the disadvantage is to notch the mouth, stress concentration, easy to tear.

② Eye cutter eye cutter Eye cutter eye clamp similar to the train, car ticket checking tools, is the factory commonly used tools, play the rules of the eye, depth, width easy to grasp.

③ crossed the knife eye position According to the structural characteristics of the fabric, the knife at the time of sampling must be crossed to indicate.

(3) the principle of playing knife eyes

① Depth of the depth of the knife is generally around O.5cm.

② direction knife eye direction perpendicular to the net suture. Armband arm arc, for example, armband arc as a concave curve, so the hair suture to be shorter than the net suture, and sleeve arc as a convex curve, so the hair suture to be greater than the net suture. To keep net sutures equal or have set eaters, the accuracy of stitching or assembly of the part can be guaranteed only when the arc is perpendicular to the net suture.

③ knife has a special role to indicate the size of the sewing hole knife eye play, the principle is based on the sewing order to be sewn at both ends (starting and ending points) hit the knife; eye knife used for positioning, as the following hem Flap, wide noodles, slits and so on, the provincial highway, folding pleat the upper end of the zipper point, as well as pants straight pocket pocket positioning, etc .; used as a knife on the knife and eye play more flexible, generally refers to Longer seams or two parts have special assembly relationship, such as armbands and cuff arcs, collar and collar arcs, etc., according to the template design to accurately suture, the eye can be more or less, according to the specific circumstances to decide.

Drilling eye drilling also known as drilling.

(1) The role of drilling Borehole for pocket position, provincial position and so on. Because these parts are often located in the center of the film and can not use the knife to represent.

(2) .Brilling method Boring eye generally drill or chisel manual hole diameter of about 0.5cm, the size of the drill hole to facilitate the appropriate sample. Specific parts are digging the bag in the middle of the line, both ends of the advance 0.5 ~ 1cm; provincial highway in the center line, the street back 1 ~ 2cm, depending on the specific size of the provincial highway and the factory established habits to be. Strictly according to the size of provincial highway to set the eye position (as shown in Figure 2 a l3), so that the bores can be hidden in the seam, will not be damaged due to drilling the front fabric, affecting the quality of garments. For the left and right asymmetric style drilling to be positive and negative. A small circle can be used to indicate this side to be drilled.

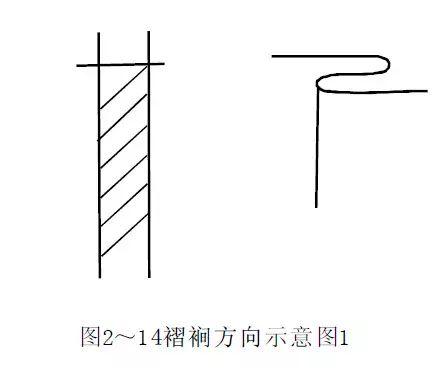

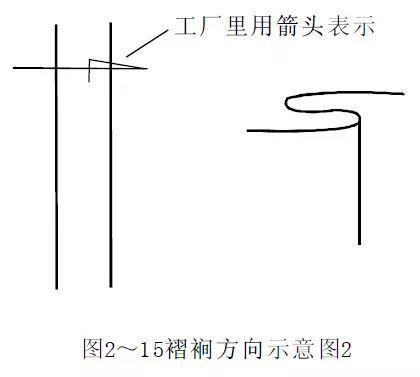

3. Provincial Highway and pleated inverted mark

In the industrial model, provincial and pleated back markers generally have the following two types:

(1). Slashes about 45 ° and the location and direction of the provincial road. The higher one is the upper one (as shown in Figure 2-14).

(2) The arrow direction indicates the direction of pleat and provincial road (as shown in Figure 2-15).

It is important to note here that the template markings are different from the markings of the cuttings. The model is the basis for nesting, patterning and cutting, requiring accurate marking, knife-edge, large drilling, which is conducive to patterning. The mark of the cutting piece is the basis of the sewing process, the depth of the eye should be narrower than the width of the sewing head, Generally half the slit head width, drilling diameter should be small, about 0.2cm, so as to avoid the seam after the exposed seam.

Third, the model of the text marked industrial model As a series of model, in order to prevent mistakes, is conducive to industrial production and archiving, need to make a text on the template mark, easy to identify.

1. Text label content

(1) the model of the silk 綹 marks and fabric down the hair forward mark. Silk 綹 mark can be used at both ends or one end of the arrow to represent, the forward mark can only be used to indicate one end of the arrow. Silk 綹 line that requires accurate, longer, try to use the template in the basic line, in order to facilitate the discharge pattern.

(2) paragraph number or customer name, code and so on. It can be expressed in Arabic numerals, Chinese and English.

(3) model name of the structure. Such as the former film, the film, the film, the sleeve, sleeve, collar, etc. must be marked. Some products around the piece of clothing asymmetric, or piece of clothing have different horizontal division, it should be marked on the left and right films, up, down or the difference between positive and negative.

(4) indicate that the model belongs to the surface, lining, bagging and setting ingredients. Some directly written in the surface, where, and some different colors to distinguish between surface, etc..

(5) Each template shall indicate the number of cut sheets or the number of discharges.

(6) model specifications. Including the number of specifications, such as 160 / 84A, 170 / 88Y, etc., the English letters S, M, L, said the size of the customer and provide some special representation.

2 text mark the requirements and model finishing

(1) Marking must be clear and accurate. The general text mark shall be capped with the text number stamp on the template. If handwriting is used instead, the handwriting must be corrected.

(2) After the completion of a set of model production, the self-check and review shall be conducted carefully according to the procedures and requirements of technical management so as to avoid any deficiency and error.

(3) Each model should be played at one end of the diameter of 10 ~ 15mm round hole, easy to perforation hanging.

(4) Model according to the size of each type of specifications, and the distinction between surface, lining, lining and so concentrated in series together, easy to manage.